Torque is one of the most important factors when it comes to choosing the right spark plugs for your engine. The amount of torque required varies depending on the type of engine, but generally speaking, you’ll need between 10 and 20 foot-pounds of torque for most applications.

There are a few things to keep in mind when selecting spark plugs based on torque.

First, make sure that the plugs you choose are compatible with your engine’s firing order. Second, consider the heat range of the plugs – you don’t want them to be too hot or too cold for your application. Finally, pay attention to the gap width – if it’s too wide or too narrow, it can affect performance.

Spark plugs are an essential part of any engine, and it’s important to know how much torque to use when installing them. Over-tightening spark plugs can damage the threads in the cylinder head, while under-tightening can cause the plugs to loosen and fall out. The ideal torque for most spark plugs is between 20 and 30 foot-pounds.

How Much Should You Torque a Spark Plug?

Most spark plugs should be torqued to between 13 and 18 foot-pounds.

How Many Pounds of Torque Does It Take to Tighten Spark Plugs?

It takes about 30-60 pounds of torque to tighten spark plugs. The specific amount of torque needed depends on the type of spark plug, the engine, and the vehicle. Make sure to consult your car’s owner manual or a mechanic to get the specific torque rating for your vehicle.

Spark plugs are an essential part of any gasoline engine. They help ignite the air/fuel mixture in the cylinders so that the engine can run. Over time, spark plugs can become fouled or damaged and need to be replaced.

When replacing spark plugs, it is important to use the correct amount of torque so that they are tight enough but not too tight.

If spark plugs are too loose, they can vibrate out of place and cause damage to the engine. If they are too tight, it can break the porcelain insulator tip which can lead to misfires and damage to the cylinder head threads.

Therefore, it is crucial to use just the right amount of torque when tightening spark plugs.

Credit: www.doghouserepair.com

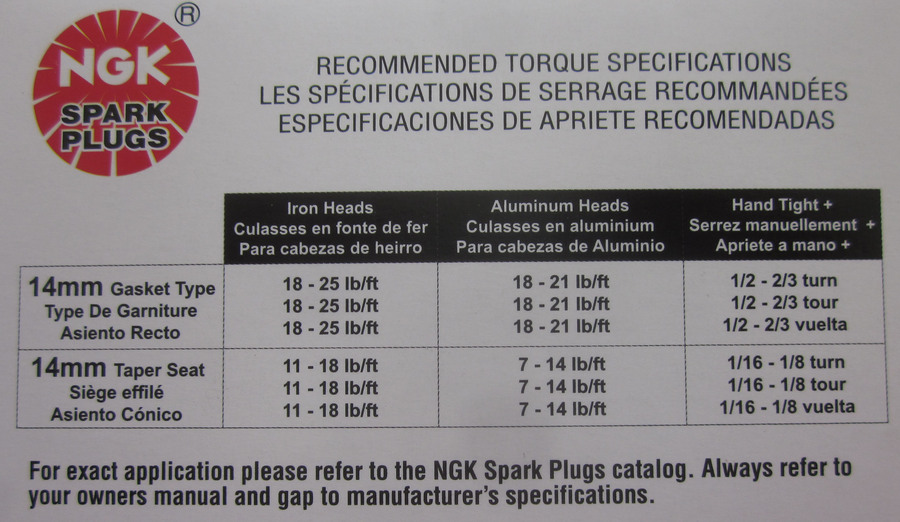

Spark Plug Torque Ngk

If you’re looking for the perfect torque for your NGK spark plugs, you’ve come to the right place. In this blog post, we’ll give you all the information you need to know about finding the right torque for your NGK spark plugs.

We’ll start by first talking about what a spark plug is and why it’s important to have the right torque.

A spark plug is a device that ignites fuel in an internal combustion engine. The spark plug has a metal threaded shell that screws into the engine’s cylinder head. The interior of the shell contains a firing tip, which protrudes into the combustion chamber, and an electrode, which extends from the firing tip to create a gap between itself and the side wall of theshell.

When an electric current flows through this gap, it produces a small plasma discharge or “spark.” This spark ignites any combustible mixture in contact with it, such as air/fuel mixture in most gasoline engines. The purpose of having proper torque on your spark plugs is so that they are tight enough to create this electrical connection but not too tight so as to damage threads or break off completely inside ofthe cylinder head.

Over-tightening can also cause pre-ignition from heat build-up on compressed side of washer face against piston crowns during engine operation. This will result in damaged pistons, rings and valves. So how do you know how much torque to use?

Using too little torque will result in loose connections that can lead tomisfiring and loss of power. Using too much torque can strip threads or break offthe ceramic firing tip inside ofthe cylinder head (usually requiring replacementof entire assembly). It is always best practice to check your vehicle’s service manualfor specific recommendations ontorque values – use these numbers as aguide rather than blindly following them without understanding why they existin first place.

With that said, here are some general tips:

For steel shells with brass washers: Use between 15-25 ft/lbs (20-34 Nm)For aluminum shells with copper washers: Use between 10-15 ft/lbs (14-20 Nm)For titanium shells with copper washers: Use between 5-10 ft/lbs (7-14 Nm)As always, consult your service manual for specific instructions related toyour vehicle make/model/year before beginning any repair or maintenanceprocedure!

Spark Plug Torque Chart

When it comes to spark plugs, there are a lot of different factors that can affect the amount of torque that’s required. The type of engine, the size of the engine, and even the age of the engine can all play a role in how much torque is needed to properly install a spark plug. That’s why it’s important to consult a spark plug torque chart before beginning any work.

There are a few different types of spark plugs, and each one requires a different amount of torque. For example, iridium plugs typically require less torque than standard copper plugs. There are also different engines sizes to consider – a smaller engine may only require around 10-15 ft/lbs of torque, while a larger engine may need 20-25 ft/lbs or more.

Age is another factor to consider when determining how much torque is needed for installation. A newer engine will likely have tighter tolerances than an older engine, meaning that less torque will be required overall. However, it’s always best to err on the side of caution and use slightly more torque rather than not enough – otherwise you risk stripping the threads or not creating enough contact for proper operation.

In general, it’s best to consult a professional mechanic or reference a reputable source before attempting any work on your own vehicle. They’ll be able to tell you exactly how much torque is required for your specific situation and ensure that everything is installed correctly and safely. However, if you’re determined to do the work yourself, consulting a spark plug torque chart is an essential first step!

5/8 Spark Plug Torque Spec

Spark plugs are one of the most important components of your engine, and it’s important to make sure they’re properly installed. The torque specification for a 5/8 spark plug is 60-70 ft-lbs. This means that you should use a torque wrench to tighten the spark plug until it reaches 60-70 ft-lbs of force.

If you don’t have a torque wrench, you can use an impact gun, but be careful not to over tighten the spark plug, which could damage the threads in the cylinder head.

14Mm Spark Plug Torque

Most engines these days require 14mm spark plugs. The correct torque for a 14mm spark plug is 18-21 lb ft (25-29 Nm). Over torquing the spark plug can damage the thread and cause a misfire.

Under torquing can cause the spark plug to loosen and fall out, also causing a misfire.

16Mm Spark Plug Torque

If you’re working on a car with a 16Mm spark plug, it’s important to know the proper torque for the job. Too much torque and you could damage the engine, too little and the plugs could come loose. The ideal torque for a 16Mm spark plug is between 20 and 30 Newton meters.

Always use a quality torque wrench when working on your car to ensure accuracy.

Torque Specs for Spark Plugs Gm

Spark plugs are one of the most important components of your car’s engine. They provide the spark that ignites the air/fuel mixture in the cylinders, and they also help to remove heat from the combustion chamber. That’s why it’s important to make sure that your spark plugs are properly torqued.

There are a few different schools of thought when it comes to torqueing spark plugs. Some mechanics will tell you to use as much torque as possible, while others will say that you should just snug them down until they’re tight. The truth is somewhere in between.

For most applications, GM recommends using 10-15 ft-lbs of torque on your spark plugs. However, it’s always a good idea to check your owner’s manual or service manual for specific recommendations.

If you’re using aftermarket spark plugs that require a different torque specification, be sure to follow the manufacturer’s recommendation.

Using too much or too little torque can damage the threads in the cylinder head and cause problems down the road.

Spark Plug Torque Wrench

If you’re a car enthusiast, then you know that one of the most important aspects of vehicle maintenance is keeping your spark plugs in good condition. A properly functioning spark plug is essential to engine performance, and it’s important to use the right tools to keep them in tip-top shape.

A torque wrench is an essential tool for any car owner or mechanic, and it’s especially important when dealing with spark plugs.

The reason for this is that over-tightening or under-tightening a spark plug can cause serious damage to the engine. That’s why it’s important to have a torque wrench that is specifically designed for spark plugs.

There are a few different types of torque wrenches on the market, but the most popular ones are digital and analog.

Digital torque wrenches are more expensive, but they’re also more accurate. Analog torque wrenches are less expensive, but they’re not as accurate. Either way, it’s important to choose a quality wrench that will last you a long time.

When using a torque wrench on your spark plugs, be sure to follow the manufacturer’s instructions carefully. Generally speaking, you should hand-tighten the plug until it seats properly, then use the wrench to tighten it an additional quarter turn. This will ensure that your spark plug is tight enough without being over-tightened.

Once you’ve tightened your spark plug with a torque wrench, be sure to check it periodically to make sure it’s still snug. If you notice that the plug has become loose, simply re-tighten it with the wrench until it’s snug again. By following these simple tips, you can extend the life of your spark plugs and keep your engine running at its best!

Conclusion

How Much Torque for Spark Plugs?

It’s a common question with a simple answer. The correct amount of torque for spark plugs varies depending on the vehicle, but 20 pounds per square inch (PSI) is usually sufficient.

Over-tightening can damage the threads in the engine block and cause the plug to break during removal.